Ningbo Xinli Auto Parts Co., Ltd., li Zona Pêşkeftina Aborî ya Hangzhou Bay, Zhejiang, Chinaîn e, pargîdanî di Gulana 2014-an de hate tomar kirin, lêkolîn û pêşkeftin, hilberandin, firotina pargîdaniyên hilberîna hilberên pompeya otomotîvê ye.Ew ji bo mitsubishi, Nissan, Toyota, Isuzu, Hino, BMW, Volkswagen, Ford, Hyundai û gelek modelên din, r&d û çêkirina parçeyên pompê vedihewîne.

Sermaya qeydkirî ya pargîdanî 1000WRMB e, û zêdetirî 100 endamên tîmê r&d û zêdetirî 500 karmendên hilberînê hene.Pargîdanî deverek ji 1W metre çargoşe zêdetir vedigire, û qebareya firotanê ya navîn di sê salan de bi qasî 7000W e.

Hilberîna pargîdanî, alavên ceribandinê, piraniya kirîna alavên hilberîn û ceribandina pêşkeftî.Di 2015-an de, ew pejirandina pergala rêveberiya kalîteyê ya pîşesaziya parçeyên otomatîkî ISO/TS16949 derbas kir.

Pargîdaniyên ku pabendî mirovan ne, yekem kalîte, yekem karûbarê kalîteyê, lêgerîna felsefeya karsaziya hêja, teknolojiya nûjeniyê, hilberîna bêhêz ji bo ramana hilberînê, yekem xerîdar, rêveberiya yekparebûnê ji bo mebesta firotanê, ji bo lêgerîna pêşkeftina serketî ya mişteriyên.

Ningbo Xinli Auto Parts Co., Ltd., li Zona Pêşkeftina Aborî ya Hangzhou Bay, Zhejiang, Chinaîn e, pargîdanî di Gulana 2014-an de hate tomar kirin, lêkolîn û pêşkeftin, hilberandin, firotina pargîdaniyên hilberîna hilberên pompeya otomotîvê ye.Ew ji bo mitsubishi, Nissan, Toyota, Isuzu, Hino, BMW, Volkswagen, Ford, Hyundai û gelek modelên din, r&d û çêkirina parçeyên pompê vedihewîne.

Rêvebiriya bêhêz 6S, Kanban dîtbar, pêvajoya hilberîna standard, pakkirin û veguhestina pêbawer.Pêdiviyên xerîdarên berfireh têr bikin.Em bêtir bala xwe didin hewildanên kontrolkirina her pêvajoyê û hûrguliyên di pêvajoya hilberînê de, şêwaza rêveberiya zanistî û bi bandor, ji bo ku bigihîjin radestkirina hilberîna bikêr û kalîteya hilberîna pêbawer, dûv re karûbarê çêtirîn peyda dikin da ku hewcedariya xerîdar têr bikin.

Bi salan, em beşdarî her Automechanika Shanghai bûn, platformek negirêdayî peyda kir da ku çêtir rave bike, performansa cihêreng a pêvajoya hilber û karûbarê ji xerîdaran re ragihîne, dûv re gumanên kirîna xerîdaran çareser bike, karûbarê çêtirîn peyda bike.Di çêkirina hilberan de jî pisporiya me nîşan bidin.

Me cûrbecûr alavên danûstendinê yên bêkêmasî hene da ku pêbaweriya hilberan misoger bikin, di nav de: jûreya ceribandina germahiya bilind û nizm, sê alavên ceribandina hevrêz, projektor, detektora paqijiyê, detektora hişkbûnê, detektora hêza tansiyonê, stûna testa performansê, ceribandina simulasyona barkirina gerîdeyê û bi vî awayî.Bi navgîniya ceribandina alavên ku ji hêla hilberîna pêvajoyê ve hewce ne, qalîteya hilberê aram û pêbawer piştrast bikin.

Berî serhêla hilberê, em ê ceribandina hawîrdora germahiya bilind û nizm, ceribandina domdariyê û ceribandina simulasyona barkirina gerîdeyê ji bo nimûneyên nû pêşkeftî bikin, da ku aramiya hilberên hilberîna girseyî peyda bikin.

Em bi pêşkeftin û hilberîna meclîsên pompeya valahiya, û hem jî hilberandin û firotina pêkhateyên meclîsê ve girêdayî ne.Zeviyên têkildar di nav de: gemar, gomek, metalurjiya toz, pêlavên boriyê û hwd, ji hêla xwe ve têne hilberandin û firotin.Di vê navberê de ji bo ku xerîdar hilbijêrin, cûrbecûr pakêtên bêalî, rengîn peyda bikin.

Heya nuha, em dest bi lêkolîn û pêşvebirina pompeya avê ya otomatîkî, pompeya rêberiya hêzê, û hilberên din ên pompeya otomatîkî, hilberandin û firotina yekbûyî, modelên parçeyên hilberan serhêl bûne.

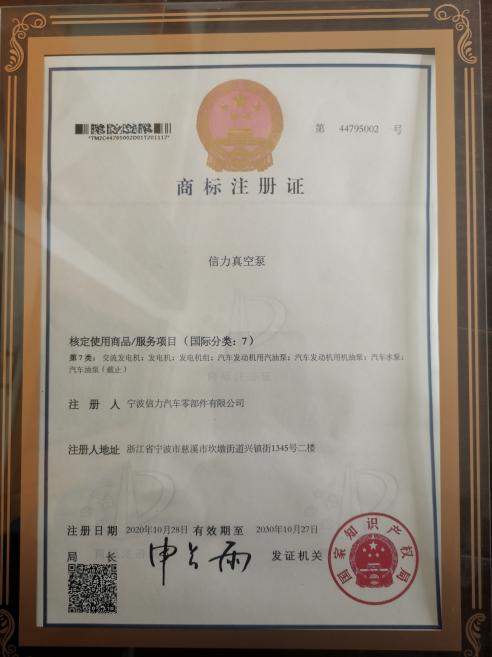

Şehade